Sustainable packaging solutions are no longer just an option in modern business operations—they are critical for responsible practices. Across industries like the medical industry, food and beverage sector, and industrial manufacturing, companies are increasingly turning to eco-friendly packaging that supports sustainable practices while maintaining high performance. A pivotal decision in this pursuit is selecting between virgin and recycled films, both of which play key roles in sustainable packaging.

As a recognized leader with over 35 years of expertise, Dallas Plastics helps businesses navigate this choice. By combining advanced manufacturing processes with a focus on quality, Dallas Plastics delivers high-performance, customizable blown film products that meet operational and environmental goals.

Understanding Sustainable Packaging Solutions: Virgin and Recycled Films

The packaging industry has adopted innovative materials that balance environmental responsibility with operational excellence. Virgin and recycled films are two prominent options driving this shift, each serving distinct purposes across various applications.

Why Eco-Friendly Packaging Matters

Adopting eco-friendly packaging solutions is essential for businesses aiming to meet regulatory requirements and consumer expectations. By prioritizing sustainability, companies can reduce their carbon footprint, align with global goals, and build trust with their audience. Innovative companies like Dallas Plastics have made great strides in offering materials that achieve these objectives. They can make many of their film products from a blend of virgin and recycled polymers.

Eco-friendly packaging not only addresses environmental concerns but also enhances brand reputation. Consumers are increasingly aware of the environmental impact of their purchases and prefer brands that demonstrate a commitment to sustainability. Additionally, regulations around packaging materials are becoming more stringent, making sustainable packaging a necessity for compliance.

Dallas Plastics: A Trusted Partner in Sustainable Packaging

Dallas Plastics embodies a commitment to sustainability by offering tailored virgin and recycled film options. Leveraging over three decades of expertise and cutting-edge technologies, Dallas Plastics produces eco-friendly materials without compromising product durability. The company’s initiatives, such as incorporating recycled materials into high-quality films, demonstrate its dedication to environmental responsibility.

By providing both virgin and recycled film options, Dallas Plastics allows businesses to choose the best material based on their specific needs and sustainability goals. Their ability to customize film properties ensures that clients receive packaging solutions that are both effective and environmentally friendly.

Request a Quote

What Are Virgin Films? Characteristics, Benefits, and Applications

Virgin films are made from new, unprocessed plastic resins, offering superior clarity, durability, and consistent quality. These qualities make virgin films a preferred option for industries with strict regulatory and performance requirements.

Benefits of Virgin Films

- Exceptional Clarity: Their pristine composition ensures unmatched transparency for applications requiring visibility.

- Versatility: They can be tailored to meet specific requirements across various industries.

- Pure & Clean:Virgin films are free from impurities and contaminants that may affect product safety.

- High Durability: Virgin films can withstand even the most demanding environments.

- Regulatory Compliance: They meet industry standards for safety in segments like medical and food packaging.

Virgin films are ideal for applications where the integrity and appearance of the packaging are paramount. Their ability to provide a clear view of the product enhances consumer trust and product appeal.

Applications of Virgin Films

Virgin films are utilized in industries where premium quality is non-negotiable:

- Medical Packaging: Suitable for sterilized wraps and pharmaceutical needs.

- Food Packaging: In the food sector, they help maintain product safety and freshness and prevent contamination

- High-Visibility Displays: Their clarity suits optical and product-covering applications. Enhance product presentation through clear and attractive packaging.

What Are Recycled Films? Benefits and Versatile Applications

Recycled films are created using reprocessed plastics such as post-consumer waste or industry scrap. Technological advancements have significantly enhanced the performance of recycled films, allowing them to close the gap with virgin films in many applications.

Benefits of Recycled Films

- Environmental Gains: Production reduces landfill waste and conserves resources. Creates a circular economy.

- Cost Efficiency: Recycled materials often represent a cost-efficient alternative for businesses.

- Durability: Modern recycling methods ensure exceptional reliability.

- Lower Energy: Requires fewer resources to produce

Recycled films contribute to a circular economy by repurposing waste materials, thereby reducing the overall environmental impact of packaging. They offer a sustainable alternative without sacrificing performance.

Applications of Recycled Films

Recycled films align with the needs of businesses that prioritize eco-conscious operations:

- Industrial Packaging: Used for products like protective coverings and drum liners.

- Sustainable Branding: Builds goodwill with environmentally aligned consumers.

- Retail Packaging: Offers eco-friendly options for product presentation without compromising quality.

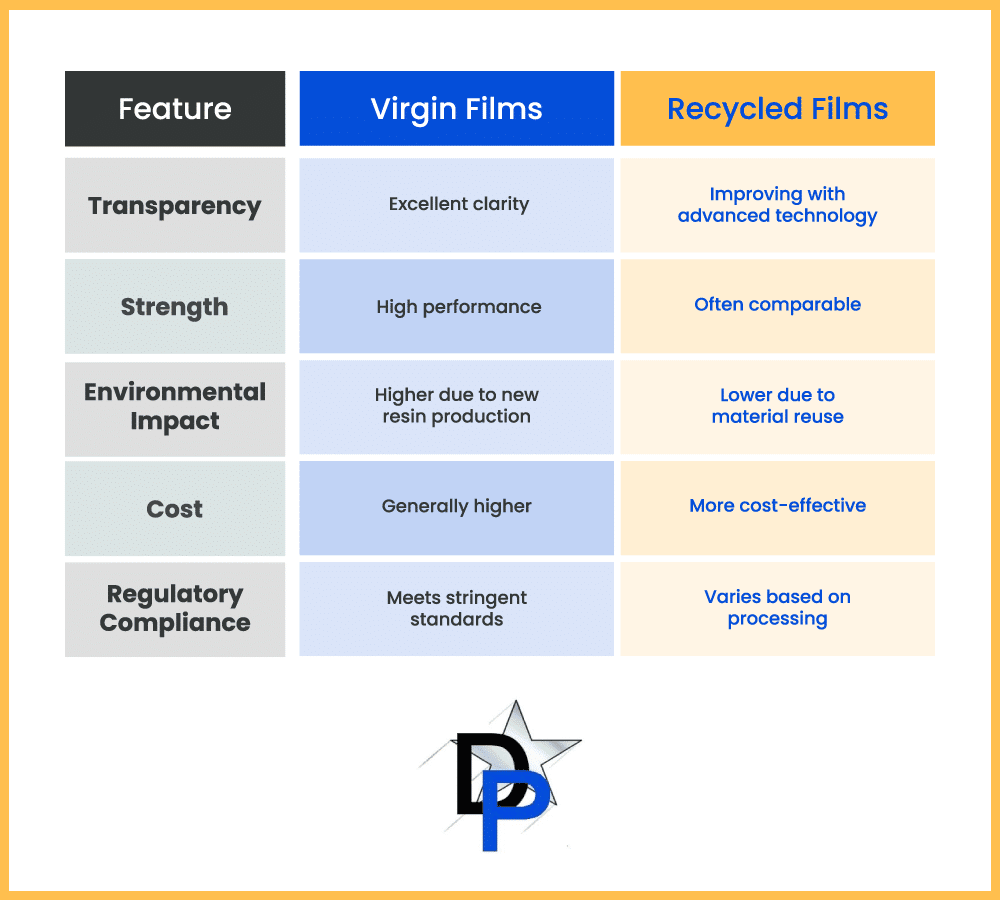

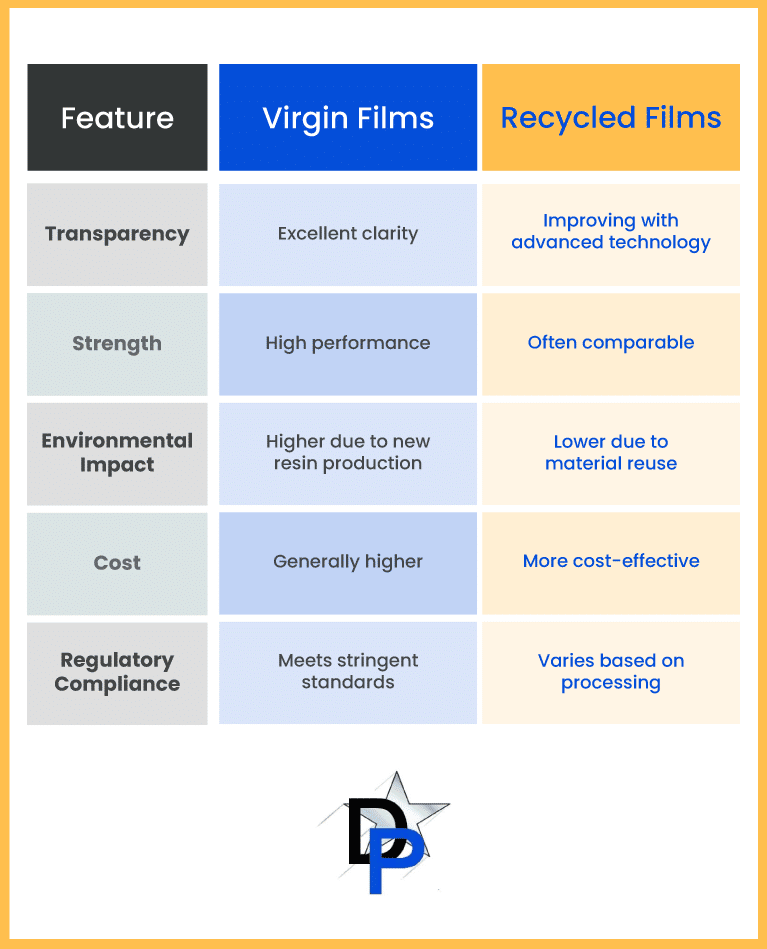

Virgin vs. Recycled Films: A Comparative Perspective

Both virgin and recycled films bring unique value. Choosing between them depends on the specifics of a company’s operational priorities:

Transparency

Virgin films are renowned for their excellent clarity, making them highly desirable for applications that require high visibility. Recycled films, while traditionally less clear, have improved significantly with technological advancements, closing the gap and becoming a viable option for many uses.

Strength

In terms of strength, virgin films generally offer superior performance, ideal for demanding settings that require robust packaging. However, recycled films are often comparable due to modern recycling techniques that enhance their quality. This improvement in recycled films ensures that they can also meet the performance expectations in various industrial scenarios.

Environmental Impact

The environmental impact of these films is another critical factor. Virgin films tend to have a higher environmental footprint because they involve the production of new resins. Conversely, recycled films boast a lower environmental impact as they utilize post-consumer waste and industrial scrap, contributing positively to resource conservation and waste reduction efforts.

Cost

When it comes to cost, virgin films are generally more expensive due to the use of new materials and the processes involved in their creation. On the other hand, recycled films represent a more cost-effective solution for businesses, appealing particularly to those aiming to minimize costs while adhering to sustainable practices.

Regulatory Compliance

Regarding regulatory compliance, virgin films are known to meet stringent industry standards, which makes them a reliable choice for sectors with strict requirements, like medical and food packaging. However, recycled films can vary in this realm depending on the processes they undergo. Nonetheless, advancements in recycling processes continue to enhance the compliance profile of recycled films, making them increasingly competitive.

When deciding between virgin and recycled films, companies must consider factors like budget constraints, environmental commitments, and specific application requirements. Both types of films can be tailored to meet diverse needs, making them versatile options for sustainable packaging.

Blending Virgin and Recycled Films

In many cases, production requires a strategic mix of virgin and recycled materials to balance purity requirements with environmental considerations. This approach is crucial for adhering to environmental regulations that aim to minimize new plastic production. The optimized ratio of virgin to recycled material depends on the intended use, required quality, and end application.

Advantages of Blended Films:

- Enhanced Performance: Combines the clarity and strength of virgin films with the sustainability benefits of recycled materials.

- Cost Savings: Using a mix of virgin and recycled materials can significantly reduce procurement costs while maintaining product quality.

- Sustainability: Supports waste reduction and resource conservation without compromising quality.

- Regulatory Compliance: Many industries are required to incorporate recycled materials to minimize new plastic production and meet environmental standards.

Blended films are particularly beneficial for applications that require both high performance and sustainability, offering a middle ground that leverages the strengths of both virgin and recycled materials.

Enhancing Production Techniques for Blending Virgin & Recycled Materials

To effectively blend virgin and recycled materials in plastic film production, several advanced techniques and technologies are employed to maintain quality and efficiency.

Advanced Filtration Systems

Using continuous screen changers with high filtration capacities ensures the removal of impurities, which is vital for producing high-purity films. This technology allows for uninterrupted production, maintaining the quality necessary for sensitive applications like food and medical packaging.

State-of-the-Art Equipment

Innovative equipment, such as screen changers, offer exceptional filtration and durability. These screen changers are designed to handle high pressures and reduce the need for frequent maintenance, making them ideal for blending materials without compromising quality.

Co-Extrusion Techniques

Co-extrusion allows for the creation of multi-layered films where specific layers can be tailored with different material blends. This technique optimizes film properties and performance, enhancing strength, barrier characteristics, and flexibility.

Process Automation

Implementing automated systems in the production process increases precision and reduces human error. Automation ensures consistent mixing ratios and adherence to quality standards, improving overall product reliability.

Quality Control and Testing

Regular monitoring and testing of film properties ensure that the blends meet all necessary standards. Advanced testing methods help identify any deviations in material composition, allowing for quick adjustments to maintain quality.

Regulatory Compliance and Quality Assurance

Compliance with industry standards is paramount in packaging solutions. Dallas Plastics adheres to current Good Manufacturing Practices (cGMP) to ensure that all products meet stringent quality and safety standards. This commitment to regulatory compliance guarantees that both virgin and recycled films are suitable for use in sensitive applications like medical and food packaging.

Quality Assurance Measures:

- Rigorous Testing: Ensuring materials perform consistently under various conditions.

- Traceability: Keeping detailed records of material sources and processing methods.

- Continuous Improvement: Implementing feedback and advancements in technology to enhance product quality.

By maintaining high standards in quality assurance, Dallas Plastics ensures that their packaging solutions are reliable, safe, and effective across all applications.

Economic and Environmental Benefits

Choosing the right type of film has significant economic and environmental implications. Virgin films, while offering superior performance, come with higher material costs and a larger environmental footprint due to the production of new resins. On the other hand, recycled films provide a cost-effective and environmentally friendly alternative, reducing waste and conserving resources.

Recycled Films Economic Benefits:

- Reduced Material Costs: Recycled films typically cost less than virgin films.

- Energy Savings: Manufacturing recycled films consumes less energy compared to producing virgin resins.

- Waste Management: Utilizing recycled materials helps in managing industrial and post-consumer waste effectively.

Recycled Films Environmental Benefits:

- Lower Carbon Footprint: Recycled films result in fewer carbon emissions during production.

- Resource Conservation: Repurposing existing materials reduces the need for virgin resources.

- Waste Reduction: Diverts plastic waste from landfills, contributing to a cleaner environment.

Businesses can achieve significant cost savings and contribute to environmental conservation by opting for recycled films, making it a strategic choice for sustainable operations.

Future Trends in Sustainable Packaging

The packaging industry is continuously evolving, with sustainability at the forefront of innovation. Future trends include the development of biodegradable films, increased use of recycled materials, and advancements in production technologies that enhance the performance of sustainable packaging solutions.

Emerging Trends:

- Biodegradable Films: Materials that break down naturally, reducing long-term environmental impact.

- Smart Packaging: Incorporating technology for enhanced functionality and interactivity.

- Circular Economy Models: Designing packaging with the end-of-life cycle in mind, promoting reuse and recycling.

Dallas Plastics is poised to lead these advancements by investing in research and development, ensuring their products remain at the cutting edge of sustainable packaging solutions.

Additional Customized Solutions for Diverse Needs

Dallas Plastics understands that each industry has unique packaging requirements. To address this, they offer a range of customization options in addition to virgin and recycled films:

- Custom Resin Blends: Tailoring the chemical composition to meet specific performance criteria.

- Printing and Lamination Treatments: Enhancing aesthetics and functionality through specialized treatments.

- Wind Configurations: Adjusting the roll size and shape to fit different production lines.

- Color & Clarity: Customizable color and clarity options to enhance product presentation and brand identity.

- Property Additives: Incorporating additives to enhance properties like UV resistance, anti-static, or slip.

- Embossing: Adding texture to enhance product appeal and grip.

These customization capabilities ensure that businesses receive packaging solutions that are not only sustainable but also perfectly aligned with their operational needs and brand identity.

Partner with Dallas Plastics for Sustainable Solutions

Dallas Plastics combines innovation with expertise in offering customizable film solutions that address both operational and ecological priorities. Their comprehensive range of high-quality blown films is designed to meet the diverse needs of various industries while supporting sustainability goals.

By partnering with Dallas Plastics, businesses gain access to:

- Expert Consultation: Guidance on selecting the best materials for specific applications.

- Tailored Solutions: Customized films that align with both performance and sustainability requirements.

- Reliable Support: Dedicated customer service to assist with every stage of the packaging process.

Contact us today to explore our comprehensive range of high-quality blown films designed with sustainability in mind. Let Dallas Plastics help you achieve your packaging goals while contributing to a greener future.