Imagine a material so versatile it can wrap the freshest produce, protect life-saving medical equipment, and streamline your online shopping deliveries—all while supporting sustainability goals. Flexible plastics drive innovation across industries.

This article explores their defining properties, diverse applications, and crucial role in modern manufacturing and environmental stewardship. By the end, you’ll see how these adaptable materials support innovation and address environmental considerations.

The Versatility of Flexible Plastic

Flexible plastic is an indispensable material, offering versatility and efficiency across countless industries. At its core, it is designed to bend, stretch, or conform to various shapes without breaking—unlike rigid plastics that maintain a fixed form. This adaptability makes flexible plastic a critical solution for packaging, storage, and protective applications, addressing the diverse needs of both businesses and consumers.

In everyday life, flexible plastic is everywhere. It appears in resealable food storage bags, trash liners, and numerous other items that simplify daily tasks due to their lightweight, durable, and cost-effective properties. Dallas Plastics, a leading manufacturer of blown film products, focuses on delivering high-quality plastic solutions that serve many different sectors. Notably, converters represent Dallas Plastics’ largest customer sector, requiring reliable, specialized converter-grade sheeting for advanced packaging across various industries, including food, medical, and industrial.

Modern innovations are shaping a more sustainable future for flexible plastic. From eco-friendly additives and recycle-friendly film designs to renewable resin technologies, manufacturers continue to evolve formulations to meet global sustainability goals. Paired with regulated manufacturing standards like current Good Manufacturing Practices (cGMP), flexible plastics can balance functionality with environmental responsibility, offering efficient, high-quality solutions that reduce waste and extend product lifespans.

Properties of Flexible Plastics

Flexible plastics owe their widespread popularity to a combination of key properties that make them indispensable across industries. Unlike many rigid materials, they seamlessly adapt to various applications, balancing strength, durability, and customizability to meet specific requirements.

The flexible plastic demand continues to grow as manufacturers seek out materials that can provide high-performance characteristics while remaining cost-effective.

Adaptable and Customizable

Processes like multi-layer coextrusion allow manufacturers to fine-tune films by selecting specific plastic resins or blending multiple layers to match precise dimensions, thickness, and performance needs. Each layer can serve a unique function—such as providing puncture resistance or superior moisture barriers—which is particularly valuable in industries like food packaging and medical supplies.

Strength Without Sacrificing Flexibility

Despite their pliable nature, modern flexible plastics are remarkably durable. Advances in polymer science have produced films that resist tears and punctures while remaining thin and lightweight. Specialized resins or performance-enhancing additives can further optimize these materials for specific needs, such as extreme temperature tolerance or enhanced tensile strength. This combination of strength and flexibility ensures reliable performance in demanding applications, from industrial packaging to medical-grade films.

Reliable and Safe Manufacturing Standards

Producing flexible plastics for critical applications, such as medical or food packaging, requires strict adherence to regulations. Compliance with cGMP guidelines, for instance, helps manufacturers maintain the highest benchmarks of quality and safety. By implementing rigorous processes, producers can reduce contamination risks, maintain consistency, and deliver materials fit for stringent regulatory requirements.

Enhanced Performance Through Specialized Additives

The addition of specialty additives can further extend the functionality of flexible plastics. Whether it’s UV protection for agricultural film or antimicrobial properties for medical packaging, these enhancements provide substantial versatility. Some applications benefit from multiple property adjustments, such as clear food packaging with both high strength and strong oxygen-blocking capabilities.

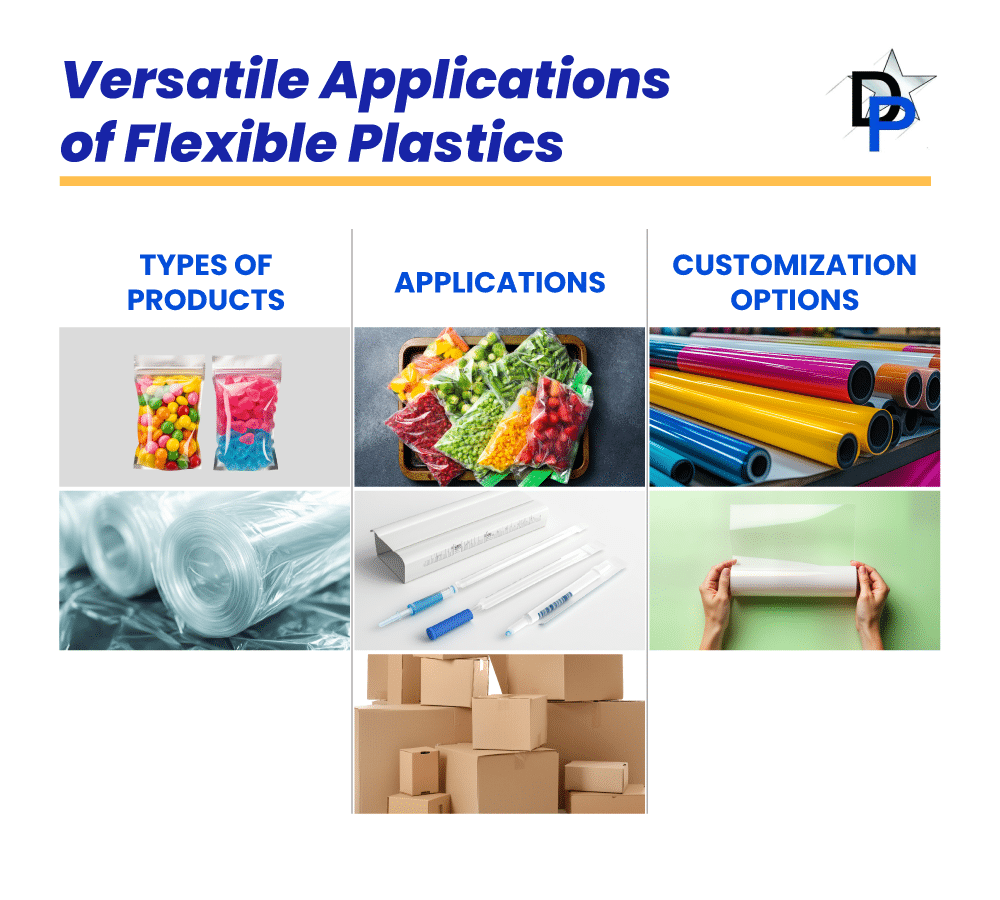

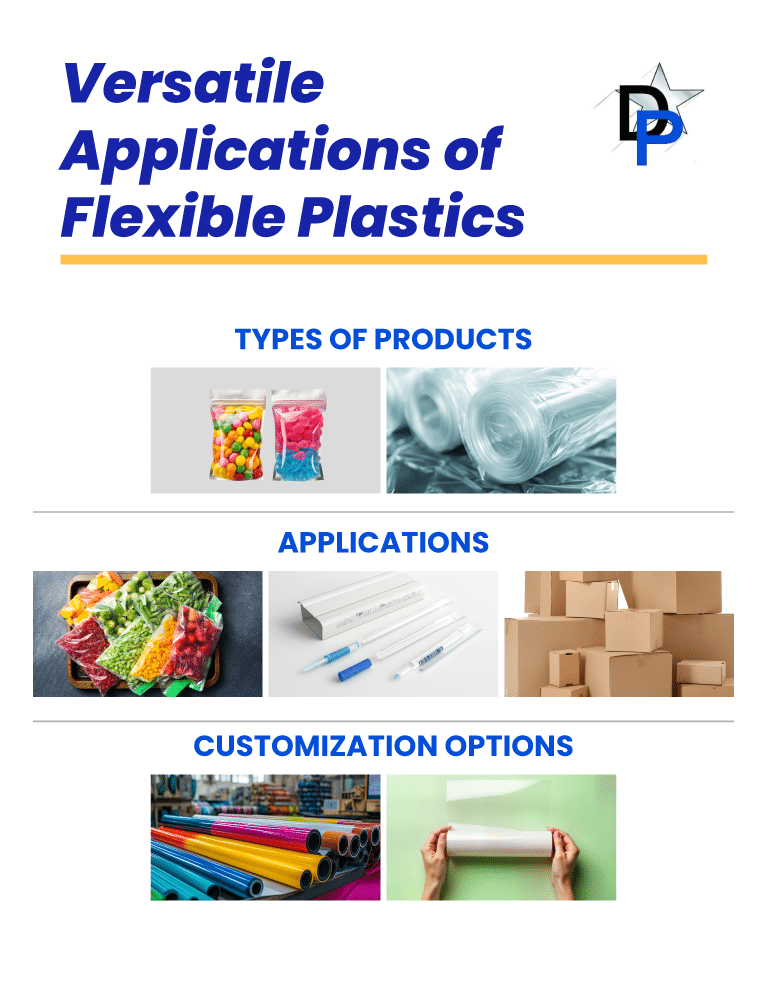

Types of Flexible Plastic Products

Flexible plastic is pivotal in various industries, offering a wide array of customizable products tailored to meet specific needs. From everyday items to specialized industrial solutions, these products combine functionality, durability, and cost-effectiveness.

Bags on Rolls and Trash Liners

- Daily Use: Resealable food storage bags and trash liners provide convenient, reliable solutions for packaging and waste disposal in both commercial and residential settings.

- Industrial Use: Heavy-duty liners manage larger volumes of waste, minimizing spillage and maintaining cleanliness in industrial environments.

Shrink Film and Polyethylene Sheeting

- Shrink Film: A heat-sensitive material that tightly wraps around items, protecting against dirt, moisture, and shifting during transportation.

- Polyethylene Sheeting: A durable barrier used in construction, agriculture, and industrial projects for moisture control, dust prevention, and surface protection.

- Customization: Available in various dimensions and thicknesses to suit specific use cases, from protecting machinery to safeguarding crops.

Specialty Products for Food, Medical, and Industrial Applications

- Food-Grade Sheeting: Ensures hygienic packaging, preserving freshness and protecting consumables from contaminants.

- Medical Packaging: Engineered to meet safety and sterility standards for products like pouches, wraps, and IV bags.

- Industrial Solutions: Custom liners for drums or bins designed to handle bulk materials, preventing contamination or leakage.

Mailer Films and Narrow Tubing

- Mailer Films: Secure, lightweight, and cost-effective shipping solutions in e-commerce, protecting items from moisture, tearing, and rough handling.

- Narrow Tubing: Ideal for bundling and packaging smaller items or loose components, ensuring efficient storage and transportation.

Custom Printing, Colors, and Clarity Options

- Design Potential: Enables custom printing, vibrant colors, and varying levels of transparency for branded packaging.

- Consumer Appeal: Clear flexible plastic packaging enhances visibility, while opaque or colored films provide privacy and light protection for items like pharmaceuticals or perishables.

Applications of Flexible Plastics Across Industries

Flexible plastic has transformed how industries approach packaging, storage, and transportation. Its versatility and adaptability make it an essential material, enhancing efficiency and meeting evolving consumer and industry demands.

Medical Packaging

In the medical field, flexible plastic is crucial for sterilized packaging that requires safety and reliability. From protective films for surgical instruments to sealed wraps for pharmaceuticals, this material ensures that products remain uncontaminated until use. Its durability prevents punctures and tears, while its lightweight nature enables easier handling and storage.

Industrial Applications

Industrial environments demand robust solutions for bulk packaging and protective coverings—needs that flexible plastic fulfills effortlessly. Common uses include:

- Box Liners and Drum Liners: Secure powders, chemicals, and other materials.

- Corrosion-Resistant Films: Serve as barriers against dust, moisture, and environmental factors.

- Flexible Wrapping: Protects tools, pallets, or machinery during storage and shipping.

Durability and easy cleanup also reduce the risk of cross-contamination, helping businesses maintain efficiency and safety in industrial settings.

Food and Beverage Packaging

Food and beverage companies rely heavily on flexible plastic for its ability to preserve freshness, ensure safety, and extend shelf life. Common uses include:

- Resealable Pouches and Vacuum-Sealed Packaging: Shield products from moisture, oxygen, and contaminants.

- Form, Fill, and Seal (FF&S) Solutions: Seamlessly package items like dried fruits, coffee, and snacks in a cost-effective process.

- Consumer Convenience: Includes tamper-evident seals and resealable closures for enhanced safety and usability.

Its lightweight, customizable nature also helps reduce food waste by improving storage efficiency and product accessibility.

E-commerce and Transportation

E-commerce has intensified the use of flexible plastic in packaging and shipping solutions:

- Mailer Films: Protects products against damage during transit while minimizing shipping costs.

- Reinforced Packaging Films: Offers durability and security for items of varied sizes and types.

- Narrow Tubing and Pallet Wrapping: Groups products efficiently, simplifying inventory management and logistics.

- Moisture-Resistant Solutions: Ensures safe delivery even in harsh conditions.

By balancing durability, adaptability, and cost efficiency, flexible plastic has become a mainstay in both industrial and consumer-facing applications.

Benefits of Flexible Plastics

Flexible plastics offer a range of advantages that make them indispensable. From streamlining production processes to enhancing user convenience and addressing environmental concerns, these materials continue to demonstrate their value across the supply chain.

Enhanced Manufacturing Efficiency

Flexible plastic production is often more resource-efficient than rigid alternatives. Advanced techniques, such as extrusion, coextrusion, and lamination, help create lightweight yet highly durable materials at scale. The lower weight also reduces transportation costs and carbon emissions, supporting sustainable supply chain practices.

Convenient and Consumer-Friendly Features

Many flexible plastic designs center on user-friendly features, including:

- Resealable Pouches: Preserving freshness and reducing waste.

- Tear Notches and Adjustable Spouts: Ensuring hassle-free product access.

- Handle Placements: Adding functionality to snack packaging, household goods, and more.

Such innovations boost end-user satisfaction and can encourage repeat purchases.

Environmental Impact Mitigation

When managed responsibly, flexible plastics can help reduce environmental impact:

- Reduced Material Use: Thinner, lighter structures require fewer raw materials than rigid packaging without compromising performance.

- Recyclable Films and Eco-Friendly Formulations: Ongoing initiatives to develop recyclable solutions and bio-based resins align with circular economy principles.

- Post-Consumer Recycled Content: Incorporating post-consumer recycled content highlights the potential for reusability.

According to the Sustainable Packaging Coalition, flexible materials can significantly decrease packaging weight, ultimately reducing transportation-related emissions.

Driving Innovative Sustainable Solutions

Flexible plastics continue to push the boundaries of eco-minded design:

- Single-Material Concepts: Simplify recycling by avoiding multi-layer composites.

- Bio-Based and Compostable Resins: Offer renewable alternatives to fossil-based raw materials.

- Material Reduction Strategies: Emphasize efficiency in both manufacturing and product end-of-life management.

Advancements in Flexible Plastic Technology

As technology evolves, flexible plastic keeps pace by incorporating new methods that improve functionality, efficiency, and sustainability. These advancements address industry needs ranging from packaging efficiency to ecological impact.

Innovations in Form, Fill, and Seal (FF&S) Technology

Form, Fill, and Seal (FF&S) technology has revolutionized packaging by combining forming, filling, and sealing into one automated process. Recent improvements focus on speed, precision, and material optimization, minimizing waste while ensuring consistent, high-quality packaging.

Multi-Layer Coextrusion for Superior Performance

Multi-layer coextrusion creates films in several specialized layers, each designed to meet a distinct requirement—be it tensile strength, moisture barriers, or sterility. This approach helps reduce the need for supplementary packaging materials, thus promoting efficiency and environmental stewardship.

Custom Resin Blends for Tailored Solutions

The development of custom resin blends further enhances the adaptability of flexible plastic. Formulations can be fine-tuned for durability, clarity, or specialized traits like heat resistance, ensuring the final product meets unique demands in industries from food packaging to medical supplies.

Recycled and Sustainable Film Innovations

Growing environmental awareness has led to continuous improvements in producing recycled and sustainable films:

- Incorporating Recycled Content: Using high-quality recycled materials to reduce reliance on virgin resources.

- Bio-Based Resins: Sourcing plastic from renewable feeds, lowering fossil fuel consumption.

- Refined Processing: Employing advanced cleaning techniques to ensure that recycled inputs meet stringent standards, including those required in certain food-grade applications.

Environmental Considerations for Flexible Plastics

Flexible plastics have often been scrutinized for their link to plastic waste, but an evolving conversation reveals how these materials can support sustainability when managed properly.

Dispelling Misconceptions

Not all plastics impact the environment equally. Flexible plastics generally require fewer raw materials than rigid alternatives, leading to lower resource use and reduced transport costs. Moreover, they can be designed for recyclability, reusability, or incorporation into closed-loop systems, driving responsible consumption patterns.

Recyclability and Circular Economy Potential

Several initiatives bolster flexible plastic’s place in a circular economy:

- Single-Material Designs: Simplify the recycling process.

- Grocery Store Drop-Off Programs: Collect used plastic bags and wraps for repurposing.

- Advanced Recycling Technologies: Break down laminated or multi-layer films into reusable components.

- Post-Consumer Recycled Content: Reinforces the viability of flexible plastic in a sustainable loop.

Responsible and Sustainable Production Practices

Manufacturers increasingly adopt responsible practices:

- Bio-Based Resins: Replace petrochemical plastics with renewable alternatives.

- Waste Minimization and Cleaner Energy: Lower overall material and energy consumption.

- Emission Reductions: Streamline production to reduce carbon footprints.

Such efforts underscore the industry’s commitment to balancing innovation with environmental stewardship.

Why Flexible Plastics Are Essential in Modern Industries

Flexible plastics have become indispensable across diverse sectors for their ability to merge efficiency, functionality, and sustainability. Their lightweight, adaptable nature helps businesses optimize everything from logistics to product presentation—without jeopardizing costs or eco-initiatives.

Logistics and Transportation

Flexible plastic’s lightweight design and protective qualities lower shipping costs and reduce product damage. Whether used for pallet wrapping or mailer envelopes, it can accommodate various shapes and sizes, making it integral to efficient, cost-effective transportation.

Customer-Facing Industries

Convenience and usability are critical in consumer markets, and flexible plastic delivers:

- Resealable Closures: Help maintain product freshness.

- Tamper-Proof Seals: Ensure consumer safety and confidence.

- Transparent Options: Let customers see the product before purchase.

Such attributes elevate brand reputation and consumer trust.

Highly Regulated Industries

In sectors like healthcare and food production, flexible plastic is integral to:

- Medical Packaging: Upholds sterility and regulatory compliance for devices and instruments.

- Food and Beverage: Extends shelf life and prevents contamination, meeting exacting quality standards.

Sustainability Alignment

Continual innovations align flexible plastics with eco-conscious objectives:

- Recycled Content: Lowers the reliance on virgin materials.

- Bio-Based Resins: Offers renewable feedstocks for production.

- Single-Material Solutions: Simplify disposal and support closed-loop initiatives.

These advancements allow businesses to address consumer demand for greener products without compromising performance.

A Sustainable Future: The Ongoing Evolution and Importance of Flexible Plastics

Flexible plastic remains a vital material revolutionizing industries from healthcare to e-commerce by delivering unmatched versatility, durability, and safety. Advances in resin technology, multi-layer coextrusion, and eco-minded production have solidified its role as a cornerstone in modern packaging and industrial solutions.

Beyond practicality, flexible plastics demonstrate a growing commitment to reducing waste, conserving resources, and addressing sustainability challenges. By exploring solutions tailored to unique applications, businesses can unlock major operational benefits while meeting rigorous safety standards. For industries ranging from medical to food and beverage, working with an experienced manufacturer helps ensure high-quality materials that balance environmental considerations with cutting-edge performance.

Transform your packaging efficiency and sustainability today! Request a quote from Dallas Plastics to discover our innovative, high-quality flexible plastic solutions tailored to your industry’s unique needs. Partner with us to drive your business forward with unmatched reliability and environmental responsibility.