In our daily lives, we interact with countless objects made from polymers and plastics—be it the packaging of our food, the tires on our cars, or even the fibers in our clothing. Despite their ubiquity, confusion often surrounds the terms “polymers” and “plastics,” with many using them interchangeably. However, while all plastics are polymers, not all polymers are plastics. Understanding the distinctions between polymers and plastics is essential for various industries, including medical, automotive, and packaging.

Understanding polymers and plastics is fundamental to advancing material science and developing sustainable solutions for the future. This insight underscores the importance of clarifying these terms not only for science enthusiasts and students but also for professionals in the materials science and engineering fields.

This article aims to clarify the nuanced differences between polymers and plastics by delving into their composition, structure, properties, and applications. By shedding light on common misconceptions, we hope to provide a comprehensive understanding of how these materials shape our modern world.

Composition and Structure of Polymers and Plastics

At the most fundamental level, polymers and plastics are large, chain-like molecules made up of repeating units called monomers. Imagine a polymer as a necklace, where each bead represents a monomer, and the entire string represents the polymer chain. These monomers are bonded together through chemical reactions known as polymerization, forming long chains that can exhibit a wide range of properties depending on their composition and structure.

Types of Polymers: Natural and Synthetic

Polymers and plastics can be classified into two broad categories:

- Natural polymers: These occur naturally and are essential to life. Examples include cellulose in plants, proteins in our bodies, and natural rubber from rubber trees.

- Synthetic polymers: Man-made polymers created through chemical processes. Common synthetic polymers include polyethylene, polystyrene, and nylon.

Polymer Structures

The properties of polymers and plastics are significantly influenced by their structural configuration:

- Linear polymers: Consist of long, straight chains. These polymers can slide over one another, making them flexible. Polyethylene, used in plastic bags, is a typical linear polymer.

- Branched polymers: Have side chains attached to the main chain. The branches can prevent the chains from packing closely, affecting the density and melting point.

- Cross-linked polymers: Chains are connected by bonds, forming a network structure. This linkage results in materials that are more rigid and resistant to deformation, like vulcanized rubber used in tires.

- Network polymers: Highly interconnected structures that provide exceptional strength and thermal stability, often found in epoxy resins.

By manipulating the type of monomers and the way they are linked, chemists can design polymers and plastics with specific properties for targeted applications.

Request a Quote

Properties of Polymers and Plastics

The diverse properties of polymers and plastics stem from their molecular structure and composition. Understanding these properties is crucial for selecting the right material for specific applications.

Mechanical Properties

- Elasticity: The ability to return to original shape after deformation. Elastomers like rubber exhibit high elasticity.

- Tensile Strength: Resistance to being pulled apart. Polymers with strong covalent bonds along the chain, like aramids used in bulletproof vests, have high tensile strength.

- Durability: Resistance to wear and environmental factors. Many polymers and plastics are resistant to corrosion and chemical attack.

Influence of Chain Length and Cross-Linking

- Chain Length: Longer chains usually result in higher melting points and tensile strength due to increased entanglement.

- Cross-Linking: The formation of bonds between chains increases rigidity and thermal stability, as seen in vulcanized rubber.

Thermal Properties

- Glass Transition Temperature (Tg): Temperature below which the polymer is hard and glassy; above it, the polymer is softer and rubbery.

- Melting Temperature (Tm): Applicable to semi-crystalline polymers; the temperature at which crystalline regions melt.

Key Properties of Plastics

Plastics inherit properties from their base polymers but are further enhanced or modified by additives and processing.

- Impact Resistance: Ability to withstand sudden forces without cracking. Acrylics used in airplane windows are designed for high impact resistance.

- Flexibility: Adjusted through plasticizers; PVC can be rigid (pipes) or flexible (raincoats).

- Chemical Resistance: Plastics like PTFE (Teflon) are resistant to a wide range of chemicals, making them ideal for non-stick cookware and chemical processing equipment.

- Transparency: Plastics like PMMA (acrylic) and polycarbonate are used where clarity is essential, such as in lenses and protective barriers.

Environmental Considerations and Recyclability

While polymers and plastics offer numerous advantages, their environmental footprint is a growing concern.

- Environmental Impact: Persistence in the environment due to slow degradation.

- Recyclability:

- Thermoplastics: Can be recycled by melting and reforming.

- Thermosetting plastics: Cannot be remelted once set, posing recycling challenges.

- Efforts in Sustainability: Innovations in biodegradable polymers and enhanced recycling technologies are being developed to mitigate environmental issues (MDPI).

Applications of Polymers

Polymers and plastics find uses across various industries due to their adaptable properties.

Medical Applications

- Biodegradable polymers: Used in sutures and drug delivery systems that dissolve in the body.

- Hydrogels: Employed in contact lenses and wound dressings for their moisture-retaining properties.

Automotive Industry

- Lightweight Components: Polymers like polypropylene reduce vehicle weight, improving fuel efficiency.

- Safety Features: Airbag fabrics, often made from nylon polymers, provide strength and flexibility.

Consumer Products

- Textiles: Polyester and nylon fibers are widely used in clothing for durability and ease of care.

- Electronics: Conductive polymers are being developed for flexible electronic devices, such as wearable technology.

Impact of Polymer Structure on Applications

The choice of polymer structure—linear, branched, cross-linked—directly influences suitability for specific applications, highlighting the importance of material science in product development.

Applications of Plastics

Plastics are integral to modern life, serving vital roles in multiple sectors.

Packaging Industry

- Food Packaging: Polyethylene films preserve freshness and protect against contamination.

- Retail Bags: Lightweight and durable, plastic bags are ubiquitous in shopping outlets.

Manufacturing and Construction

- Pipes and Fittings: PVC plumbing components resist corrosion and are easy to install.

- Insulation Materials: Polystyrene foam provides thermal insulation in buildings.

Medical Field

- Sterile Packaging: Plastics ensure sterility of medical equipment and disposables.

- Implants and Prosthetics: Biocompatible plastics like UHMWPE are used in joint replacements.

Contributions to the Industry

Companies specializing in plastic products produce high-quality plastic films and products, such as:

- Bags on Rolls: For industrial and food packaging.

- Box Liners and Drum Liners: Protect contents from contamination.

- Shrink Film and Polyethylene Sheeting: Used for secure packaging and protection during shipping.

- Mailer Film and Narrow Tubing: Essential for reliable and efficient packaging solutions.

By manufacturing under stringent quality standards, these companies ensure products meet high standards for diverse applications.

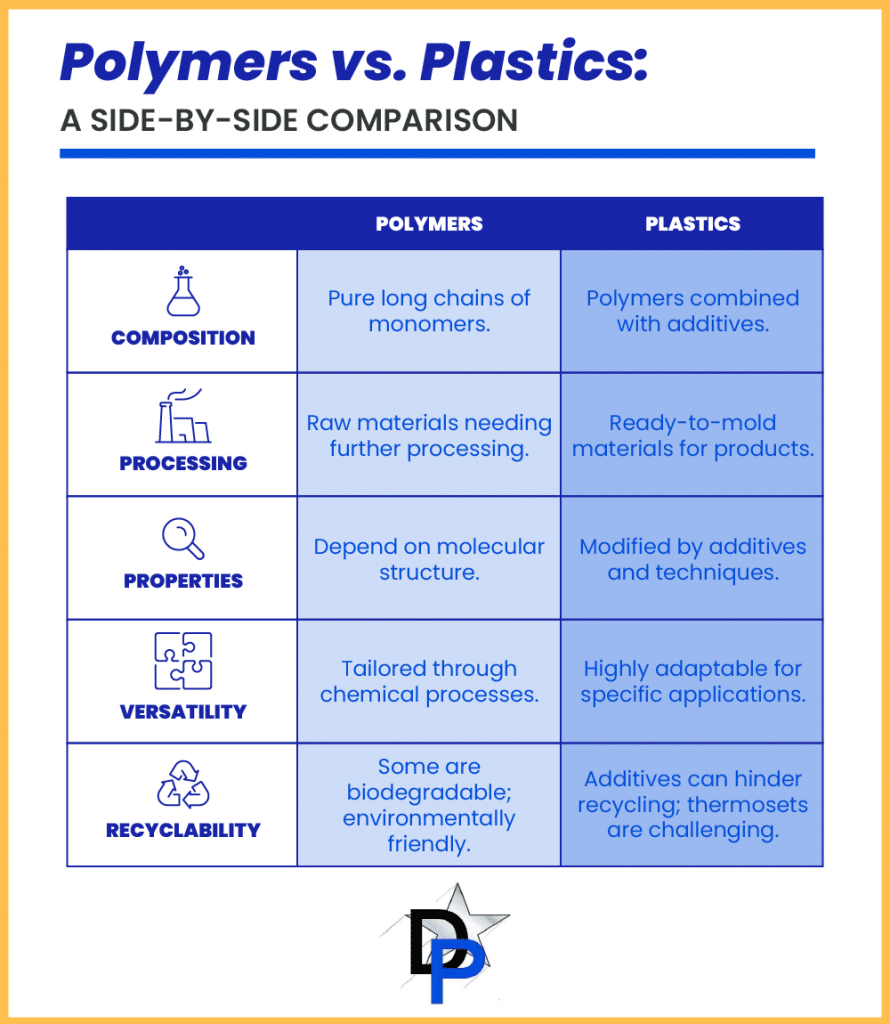

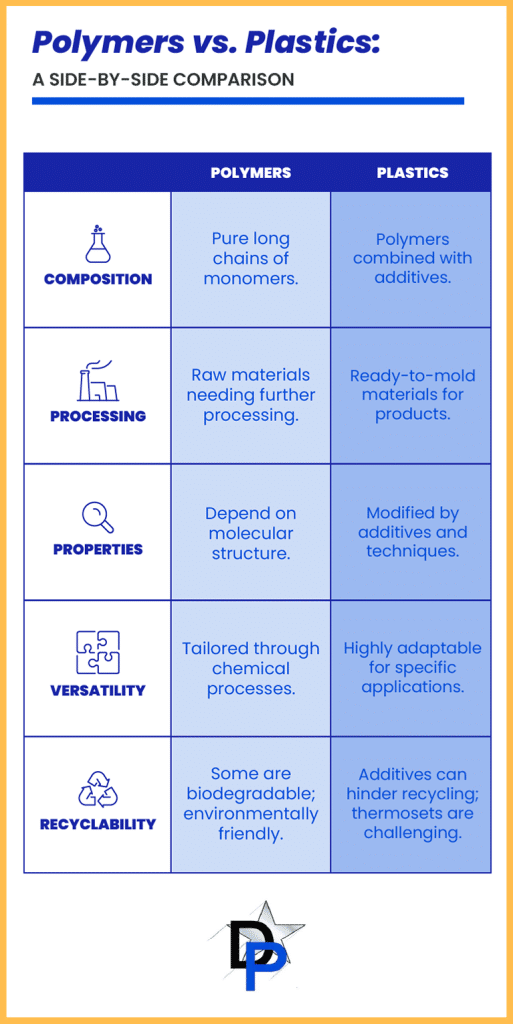

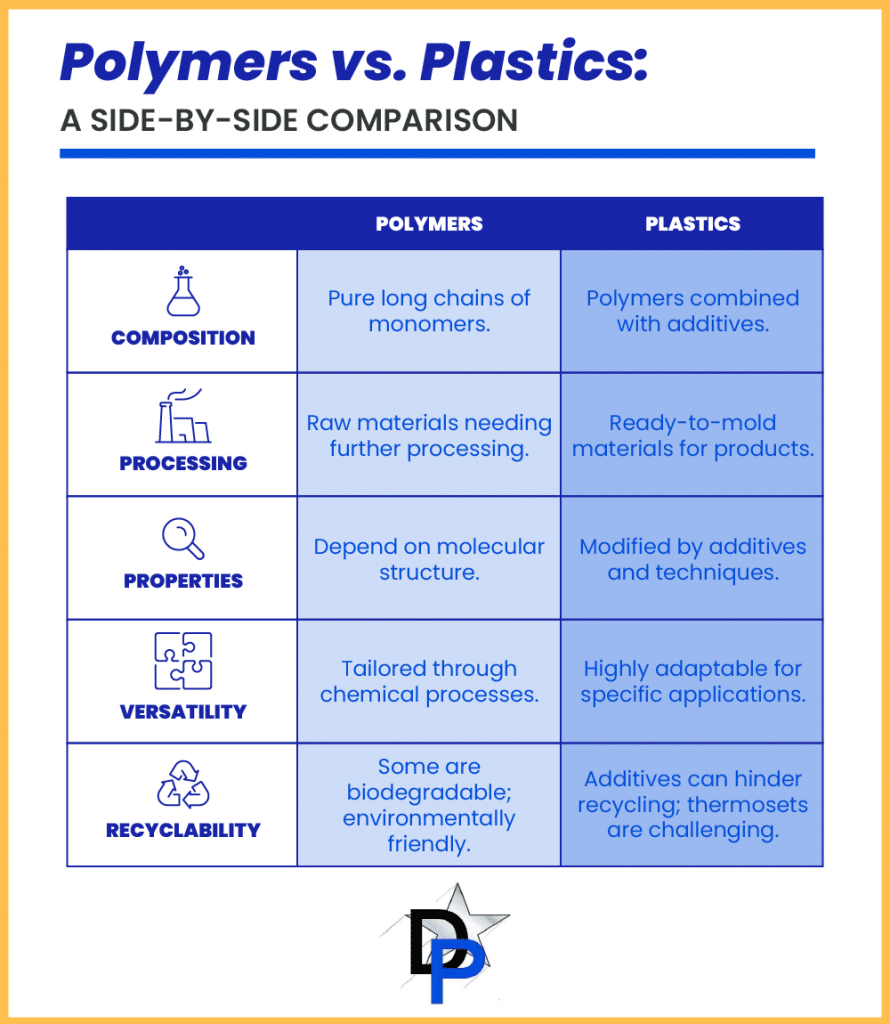

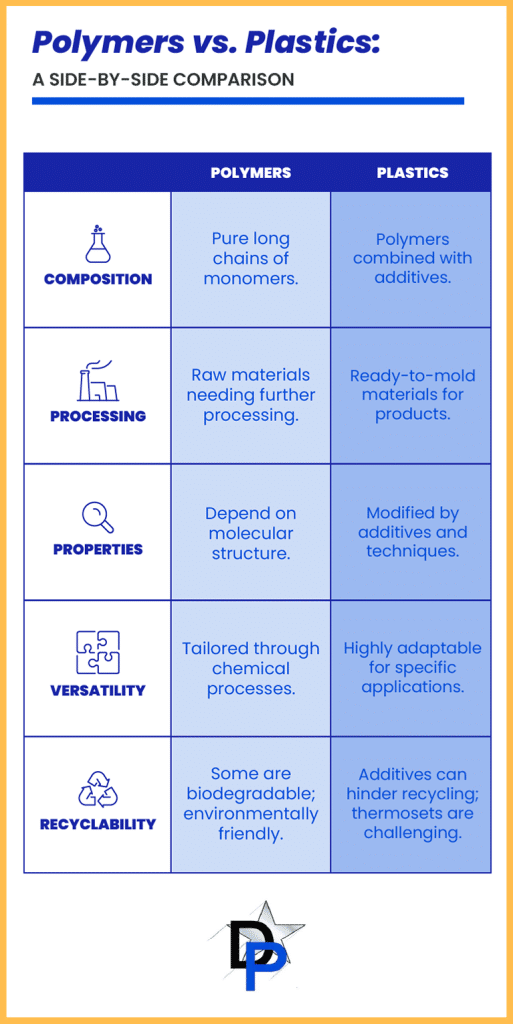

Differences and Comparative Analysis Between Polymers and Plastics

Understanding the distinctions between polymers and plastics is essential for clarity in material science.

Fundamental Differences

- Composition:

- Polymers: Pure substances consisting of long chains of monomers.

- Plastics: Formulated materials comprising polymers plus additives.

- Processing:

- Polymers: Raw materials that require further processing to be usable.

- Plastics: Ready materials that can be molded into products.

- Properties:

- Polymers: Exhibit properties based on molecular structure.

- Plastics: Properties are modified through additives and processing techniques.

Implications for Applications

- Versatility:

- Plastics: Their properties can be tailored more extensively due to additives, allowing for a broader range of applications.

- Recyclability:

- Polymers: Some are biodegradable, offering environmental benefits.

- Plastics: Additives can complicate recycling processes, especially for thermosetting plastics.

Clarifying Misconceptions

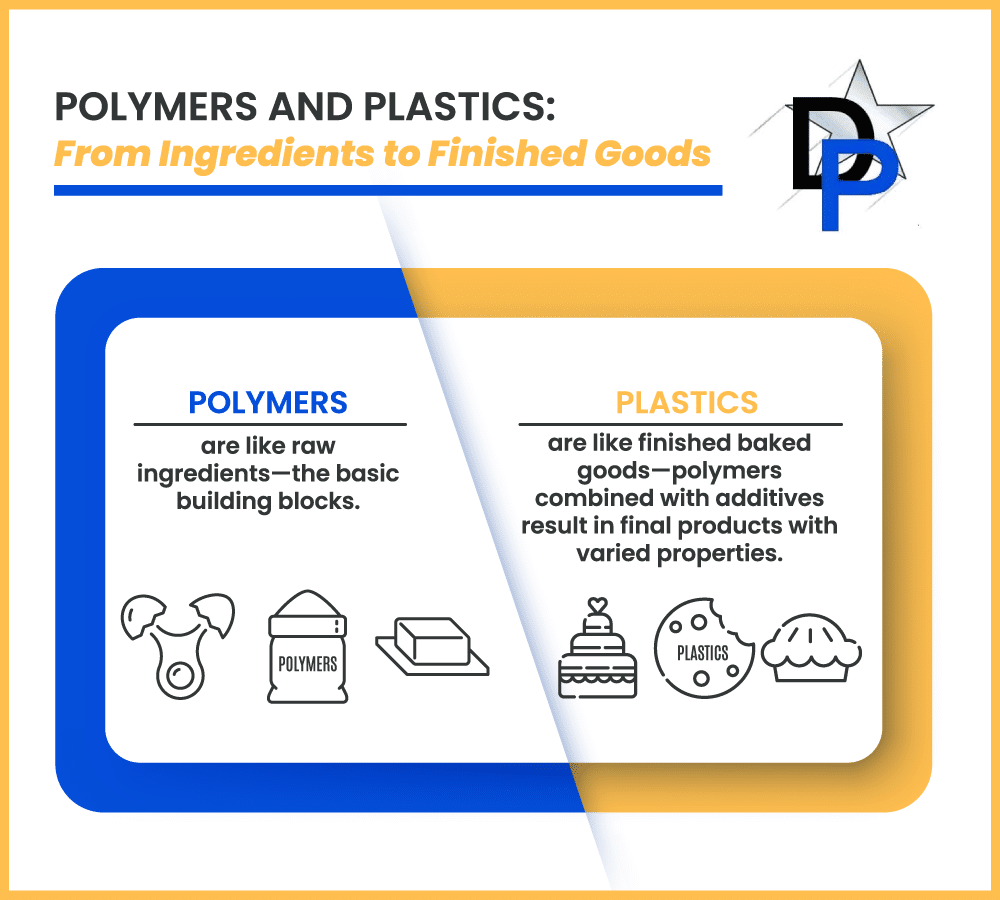

Here’s an analogy to help simplify the difference:

Think of polymers as raw ingredients (like flour and sugar), while plastics are the finished baked goods (like cookies) that contain those ingredients plus other components, resulting in a final product with different properties.

The Role of Material Science in Innovation

Material science plays a pivotal role in driving technological advancements and shaping the future of industries.

Supporting Innovation

- Development of New Materials: Research into polymers and plastics leads to materials with enhanced or novel properties, enabling breakthroughs in various fields.

- Sustainability Efforts: Creating biodegradable polymers and improving recycling processes address environmental concerns associated with plastic waste.

Impact on Industries

- Medical Advancements: Polymers contribute to new drug delivery systems and prosthetics, improving patient outcomes and quality of life.

- Electronics: Development of conductive polymers opens possibilities for flexible electronic devices, such as wearable technology and advanced computing components.

Industry Collaboration

Companies work at the intersection of innovation and application, employing material science to produce specialized products such as:

- Converter Grade Sheeting: Designed for food and medical applications requiring strict quality control and regulatory compliance.

- Custom Resin Blends and Multi-Layer Coextrusion: Allowing for the creation of highly specialized plastic products tailored to specific industry needs.

Sustainability and Environmental Impact

While polymers and plastics offer numerous advantages, their environmental footprint is a growing concern.

Production Impact

- Carbon Footprint: The plastics industry contributes significantly to greenhouse gas emissions. Production processes are energy-intensive and reliant on fossil fuels.

- Resource Consumption: Plastics primarily derive from non-renewable resources like crude oil and natural gas.

Waste and Pollution

- Non-Biodegradability: Most plastics persist in the environment for hundreds of years, accumulating in landfills and oceans.

- Microplastics: Breakdown of larger plastics leads to microplastics, which infiltrate ecosystems and enter the food chain.

- Chemical Leaching: Additives can leach into soil and water, posing risks to wildlife and human health.

Recycling Challenges

- Low Recycling Rates: According to the OECD, only about 9% of the world’s plastic waste is recycled, as reported by CleanHub.

- Economic Barriers: Virgin plastics are often cheaper to produce than recycled ones, reducing the economic incentive for recycling.

- Technical Limitations: Different polymer types and contamination hinder efficient recycling processes.

Enhancements in Recyclability

Understanding the recycling processes for polymers and plastics is vital for improving sustainability:

- Thermoplastics Recycling:

- Process: Involves melting and reforming the plastic into new products.

- Examples: Polyethylene (PE) and polypropylene (PP) are commonly recycled due to their straightforward processing.

- Thermosetting Plastics Recycling:

- Challenges: Cannot be remelted once set, making traditional recycling methods ineffective.

- Innovations: Developing chemical recycling techniques that break down polymers into monomers for repolymerization (MDPI).

- Closed-loop Recycling Systems: Promoting continuous recycling without quality degradation.

Recycling of Plastics: Challenges and Innovations

Recycling is essential for mitigating plastic pollution but faces numerous challenges. However, advancements in technology offer promising solutions.

Challenges

- Diverse Polymer Types: The variety of plastics complicates sorting and processing, making it difficult to recycle mixed materials efficiently.

- Contamination: Mixed or contaminated plastic waste reduces the quality of recycled materials, limiting their reuse potential.

- Economic Viability: High costs of recycling processes and low market demand for recycled plastics impede progress, as virgin plastics remain more economically attractive.

Innovations

- Chemical Recycling: Breaking down plastics into monomers for repolymerization enables the recycling of mixed or contaminated plastics, bypassing the need for sorting. This method holds promise for enhancing recycling efficiency and material quality.

- Pyrolysis: Converting plastic waste into usable fuels through thermal decomposition in the absence of oxygen provides an alternative recycling pathway, especially for non-recyclable plastics.

- Advanced Sorting Technologies: Utilizing AI and robotics for efficient separation of different plastic types improves the sorting process, increasing the feasibility of recycling various polymers and plastics.

Future Trends in Plastics and Polymers

The future of polymers and plastics lies in enhancing sustainability, improving recycling technologies, and developing bio-based alternatives.

Sustainable Polymers

- Bio-based Polymers: Derived from renewable resources, reducing dependence on fossil fuels. Examples include Polylactic Acid (PLA) and Polyhydroxyalkanoates (PHAs).

- Eco-friendly Additives: Development of additives that do not leach harmful chemicals, ensuring safer and more sustainable plastics.

Smart and Functional Plastics

- Self-healing Plastics: Capable of repairing damage autonomously, extending the lifespan of plastic products.

- Shape-memory Polymers: Return to their original shape upon exposure to specific stimuli, useful in applications like medical devices and robotics.

Advanced Manufacturing Techniques

- 3D Printing: Enables precise material usage, reducing waste and allowing for complex designs.

- Nanotechnology: Enhances mechanical and electrical properties through nanocomposites, leading to stronger and more efficient materials.

Circular Economy Initiatives

- Extended Producer Responsibility (EPR): Manufacturers are accountable for the end-of-life of their products, incentivizing the creation of more recyclable and sustainable plastics.

- Closed-loop Recycling Systems: Facilitating continuous recycling without quality degradation, promoting a sustainable lifecycle for polymers and plastics.

Regulatory and Policy Developments

- Global Plastics Treaty: Aims to standardize global efforts in reducing plastic pollution through coordinated policies and regulations.

- Bans on Single-use Plastics: Encouraging shifts to reusable and recyclable alternatives to minimize environmental impact.

The Future of Polymers and Plastics

Polymers and plastics are fundamental to countless aspects of modern life, from the packaging that preserves our food to the medical devices that save lives. While they are closely related, understanding the differences between polymers—the molecular building blocks—and plastics—the functional materials we use daily—is key to advancing material science and engineering.

For students, educators, and professionals, delving deeper into these distinctions unveils opportunities for innovation, sustainability, and improved applications across industries. As we continue to explore and manipulate these versatile materials, companies exemplify how expertise in polymers and plastics can lead to high-quality products that meet the evolving needs of society.

By enhancing our understanding of polymers and plastics, we contribute to a future where materials are designed with precision, purpose, and responsibility, ensuring a sustainable and prosperous world for generations to come.

To further explore the advancements in polymers and plastics or to see how Dallas Plastics can support your sustainable initiatives, visit our website and start down the path towards a greener future.

Request a Quote