High-performance films quietly play a pivotal role across medical and industrial settings, ensuring safety, enhancing operational efficiency, and helping organizations meet rigorous quality standards. Whether it is packaging solutions for delicate medical instruments or robust polyethylene sheeting for harsh industrial conditions, these versatile films are indispensable.

This article examines the key features of high-performance films, explains how advanced manufacturing supports critical industries, and highlights the importance of meeting unique sector demands. We will also discuss customization, sustainability initiatives, potential challenges, and why partnering with Dallas Plastics can yield reliable, consistently high-quality results.

The Essential Role of High-Performance Films

High-performance films are critical to both medical packaging solutions and industrial packaging solutions, where durability, functionality, and precision cannot be compromised. In such environments, these films are vital for maintaining safety and efficiency. Medical facilities rely on them to protect tools from contamination, while industrial settings depend on strong, tear-resistant materials to shield machinery or products and keep operations running smoothly.

Designed for Rigorous Environments

In medical and industrial applications, materials must withstand punishing conditions. High-performance films provide the resilience to cope with temperature swings, chemical exposure, and demanding sterilization. Within medical environments, these films serve as secure barriers against contaminants that could jeopardize patient safety. In industrial contexts, they resist abrasions, punctures, and other physical stresses, ensuring uninterrupted performance even under harsh use.

Enhancing Safety with Advanced Barrier Properties

Safety is paramount in these sectors, and high-performance films deliver robust barrier qualities to prevent contamination or damage. Hospitals depend on film seals to block moisture and microbes from sensitive items, maintaining sterility and patient safety. In industrial settings, these films protect against leaks and guard employees and infrastructure from potentially hazardous materials.

Versatile Design for Tailored Solutions

Beyond basic strength, high-performance films offer design flexibility. Manufacturers can balance thickness, clarity, temperature resistance, and other specialized features, ensuring each film meets a unique set of requirements. From antimicrobial coatings for medical packaging to rugged, puncture-resistant sheeting for industrial machinery, these films can be engineered to accommodate demanding specifications.

Key Features of High-Performance Films

While durability is often at the forefront, high-performance films are engineered for more than just toughness. By applying multiple layers of specialized resins, manufacturers create films that excel in diverse settings while delivering both functionality and reliability. Below are some standout attributes:

Multi-Layer Coextrusion

A fundamental aspect is the multi-layer coextrusion process. By combining different resin layers into a single film, manufacturers can achieve stronger barriers, higher tensile strength, and better temperature or chemical resistance. Each layer can focus on a distinct function—such as increased rigidity or flexibility—leading to comprehensive protection in medical or industrial settings.

Superior Barrier Characteristics

High-performance films maintain product integrity by resisting moisture, oxygen, and microbes. In healthcare, these barrier qualities help safeguard devices and instruments. In industrial applications, strong film barriers prevent damage during storage or transport. By providing dependable seals, high-performance films inspire confidence across healthcare and production lines.

Strength and Durability

Exceptional tear resistance and load-bearing capacity make high-performance films ideal for demanding applications. Whether they protect sensitive assets during overseas shipments or line large containers, these films consistently deliver the toughness needed to minimize damage. Their ability to endure rough handling and heavy loads proves crucial in many factory and warehouse processes.

Regulatory Compliance

Films destined for highly regulated fields—particularly healthcare and food processing—must align with stringent standards. Many of these high-performance films are produced under cGMP guidelines, ensuring product consistency and safety. Compliance fosters trust, as stakeholders know each batch meets stringent quality requirements—crucial for medical and industrial applications alike.

Importance of Compliance in Medical and Industrial Environments

In medicine and heavy industry, compliance with sector-specific regulations is non-negotiable. High-performance films must be manufactured and tested for reliability, reducing any risk of failure that could compromise safety or disrupt operations.

Upholding Safety and Reliability

When contamination or structural breakdown is simply not an option, meeting industry benchmarks helps ensure that every film provides consistent performance. From sterilizable layers in medical packaging to leak-proof drum liners in factories, these solutions uphold safety protocols. Failure to comply could impact not only product performance but also worker well-being and environmental safety.

The Role of Regulatory Standards

In healthcare, packaging solutions may need to withstand repeated sterilization without degrading. In industrial settings, films could face pressure extremes or come into contact with chemicals. Regulatory guidelines dictate how manufacturers should test, document, and evaluate film performance, helping ensure that all offerings meet rigorous quality criteria.

Dallas Plastics: A Commitment to Quality

Dallas Plastics incorporates regulatory compliance into every stage of production. Adhering to cGMP, the company manufactures consistent films that align with exacting standards—particularly vital for mission-critical sectors. Strict quality checks safeguard product integrity, supporting Dallas Plastics’ reputation as a reliable partner for specialized film solutions.

Request a Quote

High-Performance Films for Medical Applications

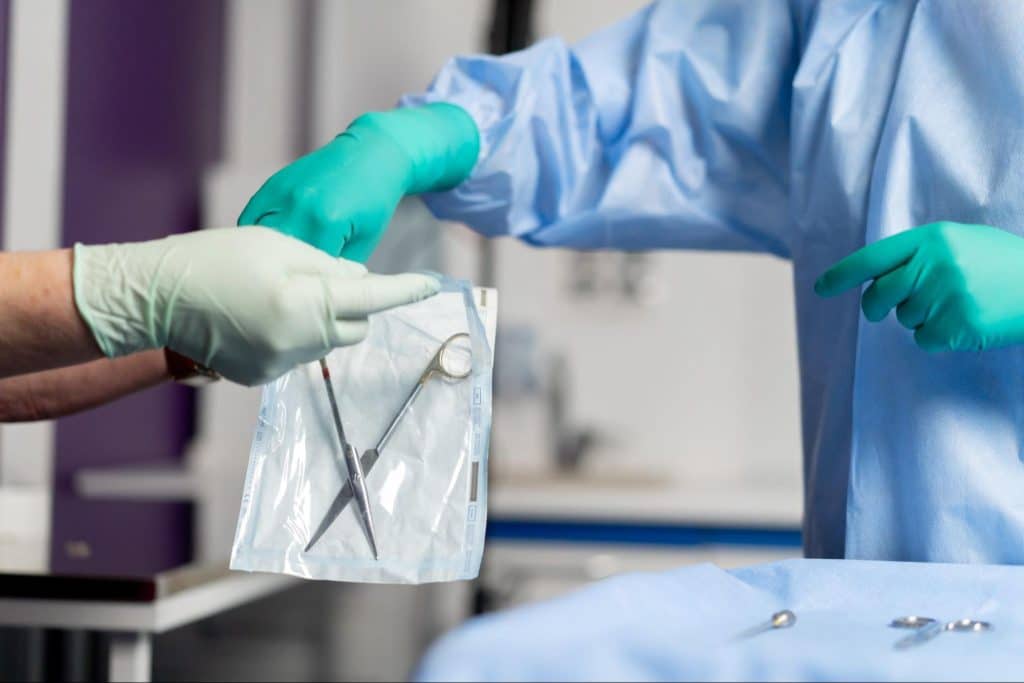

Reliable packaging in the medical field is a matter of patient well-being. Instruments and devices must stay sterile, and disruption can have grave consequences. High-performance films excel here through robust sealing capabilities and precise customization.

Ensuring Sterility and Patient Safety

One of the foremost functions of medical packaging is to preserve the cleanliness of instruments and devices. High-performance films act as impermeable barriers against dust, moisture, and pathogens—even through repeated sterilizations. Whether holding single-use items or multi-component systems, these films help medical facilities maintain strict safety standards right up to the point of use.

Versatile Solutions for Specialized Applications

Medical devices span a broad spectrum—from intricate robotics to everyday disposables. Customized film solutions can scale to a variety of products. Examples include durable packaging layered to withstand shipping stress or materials optimized to support sterilization cycles without losing structural integrity.

High-Performance Films for Industrial Applications

Industrial environments present their own set of challenges, encompassing pressure extremes, chemical exposure, and large-volume storage. High-performance films thrive in settings where durability and reliable containment are essential to smooth operations.

Meeting the Demands of Industrial Packaging

Organizations regularly transport or store heavy, abrasive, or corrosive materials, often in bulk. A torn or compromised package can lead to significant downtime. Reinforced films withstand heavy loads and rough handling, preventing leaks and minimizing the risk of damage or safety incidents.

Protective Solutions for Multiple Uses

High-performance films can serve a variety of industrial requirements, including:

- Shrink Film for wrapping and stabilizing significant loads.

- Trash Liners that resist punctures, protecting personnel and facilities.

- Mailer Film and narrow tubing for easy distribution of specific products.

This versatility ensures industrial processes receive the right combination of strength, flexibility, and barrier properties.

Enhanced Performance Through Additives

Many industrial contexts demand unique features. Incorporating specific additives into films can enhance performance, such as extra UV protection, antistatic properties, or heightened flame resistance. These modifications equip the film to provide targeted solutions in especially demanding settings.

Specialty and Customized Films

The Need for Tailored Solutions

Off-the-shelf materials do not always meet specialized demands. Customized high-performance films let businesses fine-tune characteristics like thermal stability, chemical compatibility, and mechanical strength. Such attention to detail helps organizations secure optimal materials for their operating conditions.

Advanced Options and Features

From shrink film to mailer film, Dallas Plastics also provides narrow tubing and other designs customized for different scenarios. Adapting layer composition, thickness, or other properties paves the way for unique performance profiles. This level of refinement equips customers with solutions that match exact specs, reducing risk and unnecessary complexity.

FF&S (Form, Fill, and Seal) Capability

Dallas Plastics offers high-quality FF&S (Form, Fill, and Seal) films, providing an efficient way to package medical or industrial products in a streamlined, automated process. This technology allows businesses to achieve greater efficiency by automating repetitive tasks, saving time on manual labor and enabling high-speed production runs. By reducing handling steps, FF&S can improve throughput while maintaining stringent hygiene and quality standards.

Sustainability and Environmental Responsibility

Balancing performance with environmental considerations has grown more important. Dallas Plastics’ expertise in virgin and recycled materials helps customers incorporate green initiatives without sacrificing essential product qualities. Certain industrial films can incorporate recycled content and remain strong, alleviating resource strain.

Request a Quote

Potential Drawbacks and Considerations

Despite their many benefits, high-performance films may come with challenges. For instance, advanced polymer blends can be more expensive than standard films, which could affect procurement budgets for large-scale operations.

Some formulations also require specialized storage or handling to optimize shelf life and maintain performance levels. Additionally, disposing of or recycling certain types of films can be complex, emphasizing the need for careful planning and collaboration with suppliers. By weighing these considerations alongside the benefits, organizations can make well-informed decisions that best align with their needs.

Advantages of Choosing Dallas Plastics

With over three decades of manufacturing expertise, Dallas Plastics delivers innovative approaches and proven reliability that customers count on. Here are key advantages of partnering with Dallas Plastics:

- Industry Expertise – Decades of experience providing solutions for complex, regulated environments.

- Advanced Production Capabilities – State-of-the-art equipment for customizing layers, additives, and printing.

- Commitment to Quality – Films are produced following cGMP guidelines, ensuring consistently high standards.

- Broad Product Line – Offerings include Bags on rolls, drum liners, specialty plastic films, and more.

- Sustainability Focus – Thoughtful use of materials to optimize performance and reduce environmental impact.

Elevate Your Industry Standards with High-Performance Solutions

High-performance films fulfill vital functions for the medical and industrial sectors, offering advanced barriers, durability, and customization that assure safety and efficiency. From protecting sterile instruments to containing harsh materials, these films have become integral to modern operations.

For organizations seeking reliable, top-tier packaging or film solutions, Dallas Plastics offers extensive expertise and a noteworthy track record. Whether you need high strength films for industrial feasibility or specialized medical packaging, the Dallas Plastics team stands ready to collaborate.

Take the next step to elevate your operations. Reach out today to discover more about our products or request a customized quote for your high-performance film requirements.